Robin America DY41 Specifications Page 38

- Page / 59

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

2)

Maintenance

If the test results are found not good (poor injection and "after dripping"), carefully check and repair

in

the

following

manner:

a) Disassemble the nozzle holder and nozzle, and wash

in clean light

oil.

When washng, use a wooden chip

(for instance, wooden chopstick is servicable.) for

peeling off the carbon adhered to the nozzle.

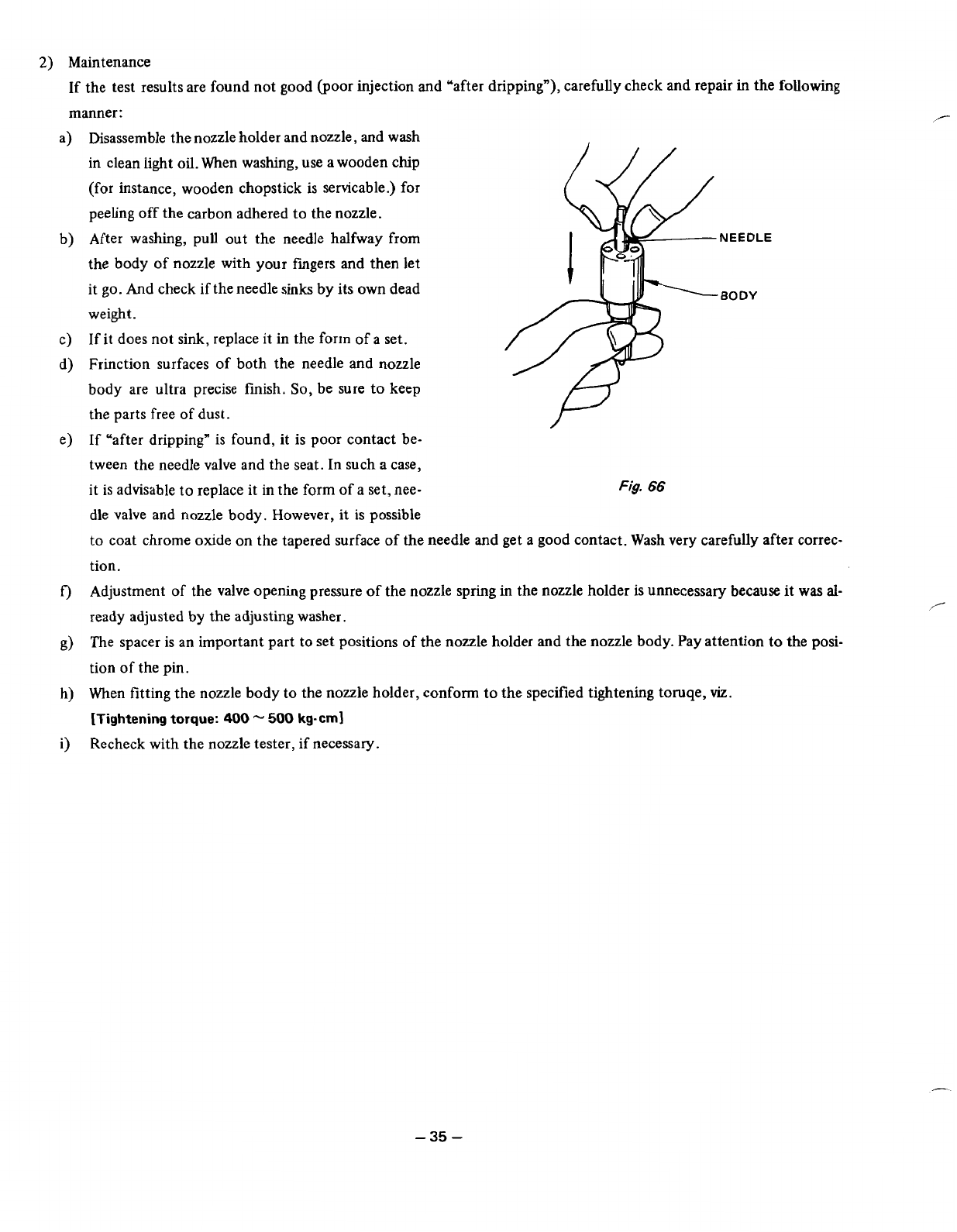

b) After washing, pull out the needle halfway from

NEEDLE

the body of nozzle with your fingers and then let

it

go.

And check

if

the needle sinks by its own dead

BODY

weight.

c) If it does not sink, replace

it

in the form of a set.

d) Frinction surfaces of both the needle and nozzle

body are ultra precise finish.

So,

be sure to keep

the parts free

of

dust.

e) If "after dripping" is found, it is poor contact be-

tween the needle valve and the seat. In such a case,

it

is

advisable to replace it in the form of a set, nee-

Fig.

66

dle valve and nozzle body. However,

it

is possible

to coat chrome oxide on the tapered surface of the needle and get a good contact. Wash very carefully after correc-

tion.

f)

Adjustment of the valve opening pressure of the nozzle spring in the nozzle holder

is

unnecessary because

it

was

al-

ready adjusted

by

the adjusting washer.

g)

The spacer is an important part to set positions of the nozzle holder and the nozzle body. Pay attention to the posi-

tion of the pin.

h) When fitting the nozzle body to the nozzle holder, conform to the specified tightening toruqe,

viz.

[Tightening torque:

400

-

500

kg-cml

i)

Recheck with the nozzle tester, if necessary.

-35

-

- AMERICA 2

- WP-185V 2

- PERFORMANCE 6

- DY35DtB 7

- LIGWWEIGWTand 8

- CYLINDER 9

- GOVERNOR 11

- Cooling 12

- FORMING 13

- SECTIONAL 14

- DISASSEMBLY 16

- ~~~~~~~ 17

- ~ ~~~ ~ ~ ~~~ ~ 17

- ~~~ ~ ~~ 17

- /." 19

- "f 20

- 23

- Install 25

- "I 27

- Because 31

- GADGETS 32

- Variation in quantity 33

- DEL,VERY 34

- HOUSING 35

- INJECTION 36

- [Tightening torque: 38

- Mechanism 39

- “Revolution Playing Angle” 40

- LUBRICATION SYSTEM 41

- LUBRICATION CHART 41

- I" 42

- INSTALLATION 43

- CORRECTIONS 44

- +" 45

- L-0.068L 46

- Description 47

- REDUCER 50

- CONFIGURATION 51

- /" 52

- COUPLING 53

- SEQUENCE 54

- (#6205) 55

- ," 56

- FLYWHEEL 57

- Industrial 59

- Engines 59

(78 pages)

(78 pages)

Comments to this Manuals